- Oregon is gearing up for a strong Fall harvest of high-quality hazelnuts

- 12+ varieties, 6 ingredient forms supporting specific needs for customizable solutions

- Experts available to optimize orders throughout the buying season

Hazelnuts Insight:

Oregon hazelnut growers are preparing for a successful harvest, expecting to bring to market 60,000 tons of premium fresh product before year-end to keep pace with fast-growing consumer demand.

The crop is coming in as top food manufacturers continue to introduce new hazelnut offerings each year as well as request samples to test and explore new flavor combinations that can elevate offerings. According to Nielsen data, already more than a dozen major food companies have hazelnut-chocolate products in-store, with over 50 SKUs booking at least $1 million in annual sales.

Ingredient buyers, new and old to working with hazelnuts, can leverage these three insights to ensure their orders deliver consistent, repeatable quality:

1. Domestic, steady supply guarantees freshness

Nearly all of U.S. hazelnut production (99%) is in Oregon, and takes no more than a few days by truck to arrive anywhere in the country. Efficient harvesting, controlled-atmosphere storage and on-demand small-batch roasting put the emphasis on freshness, the key to maximizing shelf life. With currently over 80,000 acres planted to date, and farmers continuing to add acres every year, there promises to be a reliable pipeline for fresh, locally grown hazelnuts for years to come.

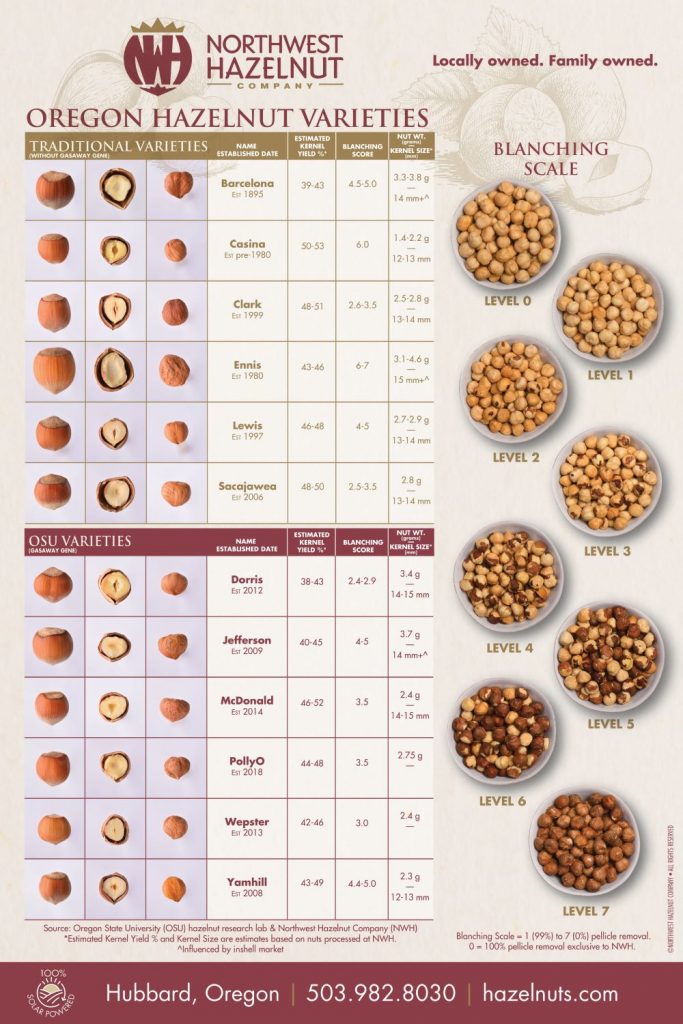

2. Over 12 varieties, 6 ingredient forms represent strategic options

Multiple types of hazelnuts are grown across the Northwest. Trees are developed to be high-yielding, disease-resistant and specially bred to meet specifications of particular industries. For example, the McDonald variety produces small, round kernel, with easily removed skin, ideal for the baking and chocolate industry whereas the Jefferson variety was developed for the inshell market because of the variety’s clean shell and large caliber size.

All nuts are available natural or roasted and in a number of convenient ingredients forms including whole, inshell, sliced, diced, paste/butter and fine meal. There are custom solutions available if a developer needs easy skin removal, blanched and even specific fat/fiber ratios. With so many options, the variety of hazelnut, level of roasting and form should be customized by product need and maintained consistently for consistent results.

3. State-of-the-art technology ensures uniform quality

Northwest Hazelnut Company, the largest U.S. processor of hazelnuts, has invested for over a decade in proprietary technology to reliably handle, separate and track varieties so that orders are of uniform quality and type, not mixed. Consistency of mass-produced foods especially relies on each shipment of kernels held to the same standards, offering identical taste, size and shape.

”Our job is to make the buyers’ job easier,” commented Rick Peterson, VP, Northwest Hazelnut Company. “We have the product expertise and technological innovations to help manufacturers and product developers produce the best performing hazelnut products possible.”

The U.S. hazelnut industry continues to spend in developing varieties and technology that can support its growth and ability to meet rising demand. Buyers can work with experts like those at Northwest Hazelnut Company to navigate the options and develop personalized solutions that meet their precise needs and specifications throughout the buying season.